Have You Got an Eye for Design Then Build Your Own Unique USB Flash Drive

USB flash drives remain one of the most popular ways to store and transport data files. They are used across all age groups and demographics and are increasingly used by companies as a way to drive sales, build loyalty and disseminate information about new products and services.

There are literally hundreds of different styles and shapes of USB drives to choose from but most of them tend to be variations around a common core them – a rectangular piece of plastic, metal or wood that is roughly 6cm x 2cm. Of course this broadly common shape helps to drive ease of use and comfort – people know what they are buying and immediately know how to use it.

The downside with this level of familiarity in a product is that it designers and manufactures tend to stay in the market “comfort zone” so we all end up with USB sticks that look pretty much the same. In a world where plenty of people want to stand out from the crowd and actually want something different, something that reflects their personality maybe the answer is to design and build something themselves.

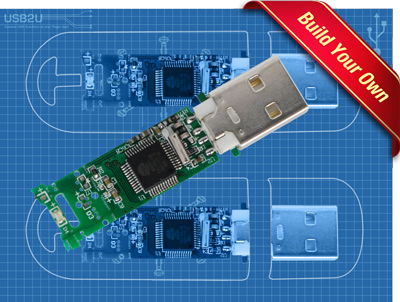

This is not as crazy as it might first sound because the core component of every USB stick is the same – it’s a PCB (printed circuit board) attached to a USB connector and embedded onto the PCB is the flash memory and a controller chip. In essence this is the USB flash drive but to make it strong enough for daily use a shell encases these components and making a unique shell is not that difficult. You just need some basic design flair, some imagination and some basic assembly skills and access to a laser cutter, some strong glue and other basic craft tools might help as well!

Lots of schools DT departments are now buying USB components and challenging their students to design and build USB flash drives as part of their GCSE course work. Companies are also commissioning custom USB flash drives often in the shape of a product or logo – these custom USB sticks are essentially “self-design and build” projects where the mould manufacture and assembly is outsourced. The companies who commission these custom USB sticks end up with something that is truly unique and something that typically stimulates lots more interest and feedback than a standard USB stick that is simply printed or engraved with a logo.

USB2U supply design & build kits if you fancy having a go yourself. Alternatively just ask them supply the fully assembled sticks – you just need to supply the idea and design!